Description

Machine Design

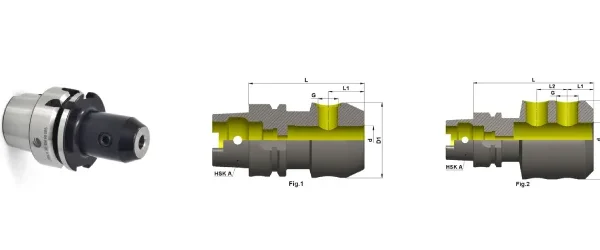

HSK tool holders are a relatively new design and is an acronym for ‘Hollow Taper Shank’ They do not have retention knobs like steep taper tool holders but instead have a hollow shank. HSK tool holders offer better repeatability, accuracy and faster tool changing and are mainly used in high – speed machining. Higher clamping force is generated due to simultaneous taper and flange contact and can be used for machining at spindle speeds higher than 8000 rpm. Falcon’s HSK tooling range includes HSK-A50, A63, A100; HSK-B63, B-80, B-100; HSK-C50, C63, C100; HSK-E50, E63, HSK-F63 and HSK-A80 as well.

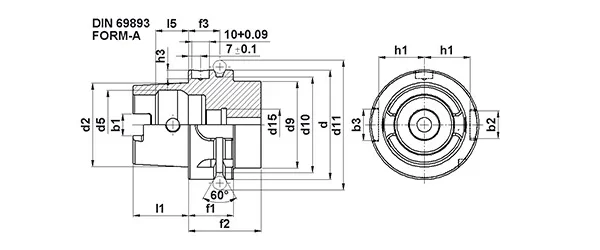

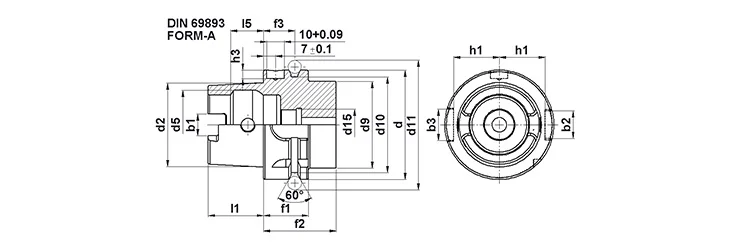

HSK Form A

Standard type for use on milling machines and machining centres with automatic tool change. Also suitable for manual tool change.

| HSK – d | b1 ±0.04 | b2 H10 | b3 H10 | d2. | d5 | d9 max | d10 -0.1 | d11 -0.1 | d15 | f1 -0.1 | f2 min | f3 ±0.1 | h1 -0.2 | h3 +0.2 | l1 -0.2 | l5 JS10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 10.54 | 12 | 14 | 38.009 | 32 | 40 | 43 | 59.3 | M16X1 | 26 | 42 | 18 | 21 | 5.1 | 25 | 14.13 |

| 63 | 12.54 | 16 | 18 | 48.01 | 40 | 50 | 55 | 72.3 | M18X1 | 26 | 42 | 18 | 26.5 | 5 | 32 | 18.13 |

| 100 | 20.02 | 20 | 22 | 75.013 | 63 | 80 | 92 | 109.75 | M24X1.5 | 29 | 45 | 20 | 44 | 4.9 | 50 | 28.56 |

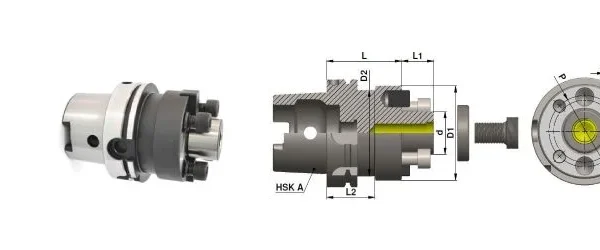

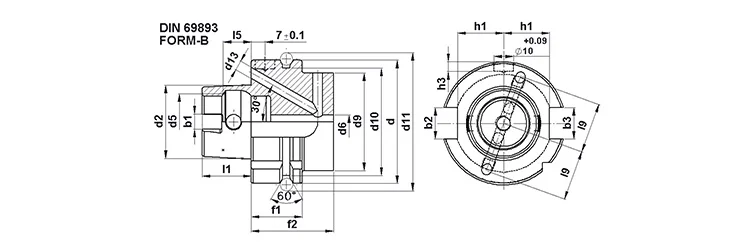

HSK Form B

Coolant supply through the flange Enlarged flange diameter for rigidity Drive slots are in the flange

For use on milling machines and lathes Machining centres with automatic tool change.

| HSK – d | b1 ±0.04 | b2 H10 | b3 H10 | d2 | d5 | d9 max | d10 -0.1 | d11 -0.1 | d13 | d6 max | f1 -0.1 | f2 min | f3 ±0.1 | h1 -0.2 | h3 +0.2 | l1 -0.2 | l5 JS10 | l9 -0.2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 63 | 10.54 | 16 | 18 | 38.009 | 25.5 | 53 | 55 | 72.3 | 25 | 6.8 | 26 | 42 | 18 | 25 | 5 | 25 | 14.13 | 25 |

| 80 | 12.54 | 18 | 20 | 48.01 | 32 | 68 | 70 | 88.8 | 32 | 8.4 | 26 | 42 | 18 | 31.5 | 4.9 | 32 | 18.13 | 32 |

| 125 | 20.02 | 25 | 28 | 75.013 | 50 | 111 | 117 | 134.75 | 50 | 12 | 29 | 45 | 20 | 50 | 4.8 | 50 | 28.56 | 50 |

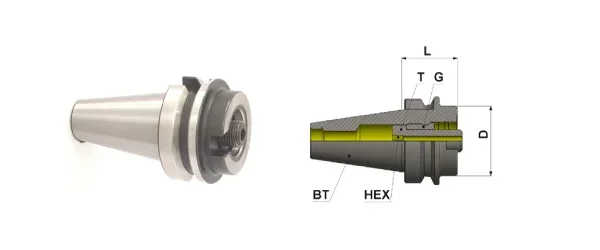

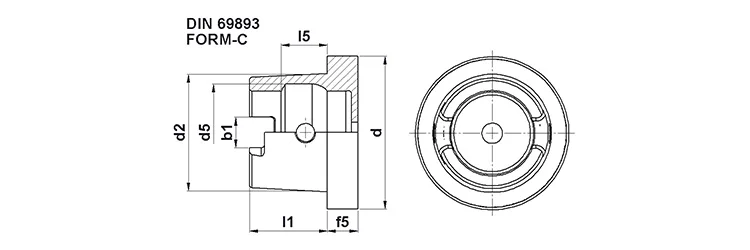

HSK Form C

Manual tool change type only For use as a modular system For special purpose machines For transfer lines and lathes.

| HSK – d | b1 ±0.04 | d2. | d5 | l1 -0.2 | l5 JS10 | f5 |

|---|---|---|---|---|---|---|

| 50 | 10.54 | 38.009 | 40 | 25 | 14.13 | 12.5 |

| 63 | 12.54 | 48.01 | 32 | 32 | 18.13 | 12.5 |

| 100 | 20.02 | 75.013 | 63 | 50 | 28.56 | 16 |

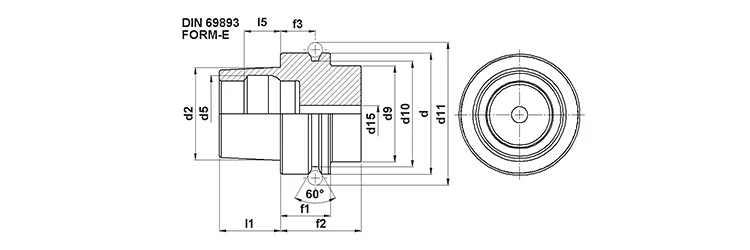

HSK Form E

- High speed applications for automatic tool change.

- Option coolant fitting as form ‘A’

- Note: No rear drive slots, no slots or notches in the flange.

| HSK – d | d2. | d5 H11 | d9 max | d10 -0.1 | d11 -0.1 | d15 max | f1 -0.1 | f2 min | f3 ±0.1 | l1 -0.2 | l5 JS10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 38.009 | 32 | 40 | 43 | 59.3 | 6.8 | 26 | 42 | 18 | 25 | 14.13 |

| 63 | 48.01 | 40 | 50 | 55 | 72.3 | 8.4 | 26 | 42 | 18 | 32 | 18.13 |

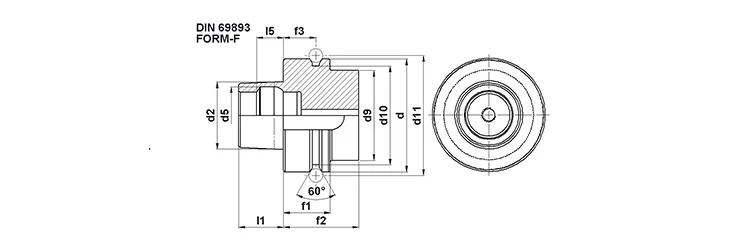

HSK Form F

- High speed applications

- Enlarged flange diameter for rigidity

- No drive slots Symmetrical design

- For use on machines with automatic tool change

| HSK – d | d2. | d5 | d9 max | d10 -0.1 | d11 -0.1 | f1 -0.1 | f2 min | f3 ±0.1 | l1 -0.2 | l5 JS10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 63 | 38.009 | 32 | 50 | 55 | 72.3 | 26 | 42 | 18 | 25 | 14.13 |

Balancing G2.5@25000 RPM