Description

Hydraulic chucks are designed to be used in applications where high accuracy and rigidity is needed.

Achieve your goals with the latest milling line-up

- Reaming

- Drilling

- Threading

Features

- Hydraulic chucks are easy to handle and easy tool changing

- With intermediate sleeves, Will have versatile clamping range

- Minimum tool run out

- Good surface finish

- Extends tool life.

Hydraulic Chucks are available in following shank

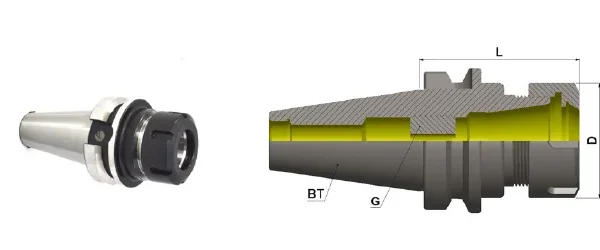

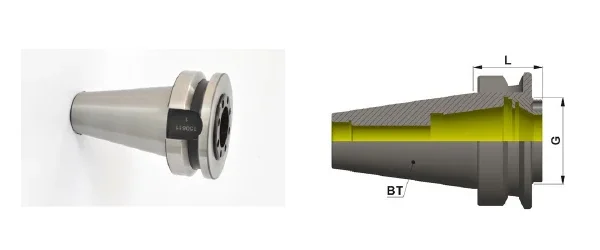

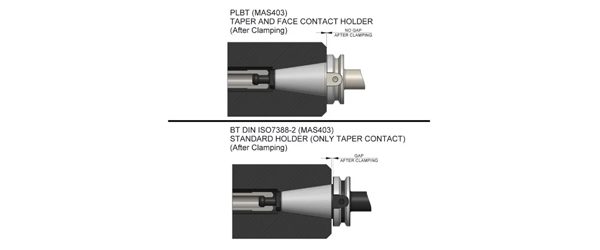

- BT(MAS 403)

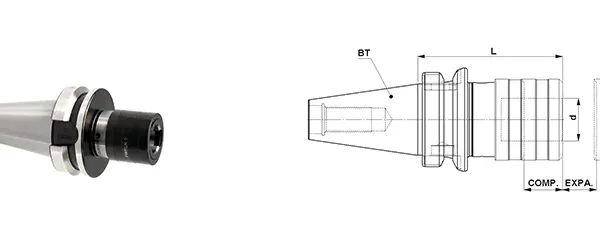

- PLBT (FACE-CONTACT)

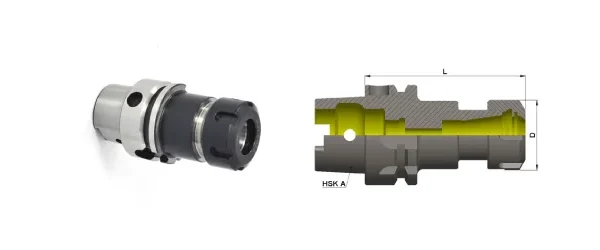

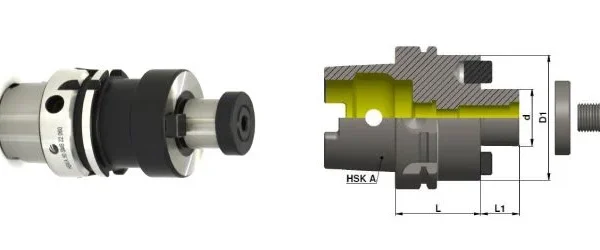

- HSK A(69893)

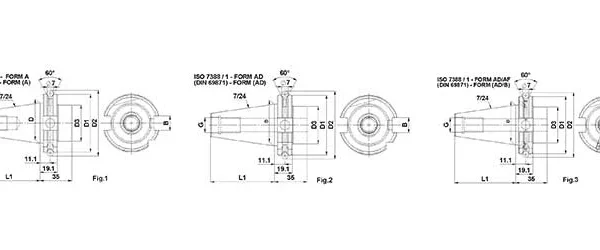

- SK(DIN69871)

Mounting Instruction

- Check tool holders for damage before each use – if damaged, do not use them.

- The max. tightening torque for the Hydraulic chuck can be found in the data sheet provided below

- To secure the clamping force, the clamping bore and groove have to be cleaned after every tool change with a cleaning agent which contain solvents(rust preventive oil).

- For the best lubrication of the clamping screw, We are recommending the use of GREASE/Copper paste (Cu7439) MOLYKOTE which has higher retention capability

Cleaning Instruction

- Holder and Bore to be cleaned with fresh cloth before use- Never use compressed air

- The contact surfaces of the tool holder and the machine must be clean

Torque Details

| Hydraulick Chuck – Heavy Duty | Hydraulick Chuck – Normal | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tool Holder Size (mm) |

ø12 | ø20 | ø32 | ø6 | ø8 | ø10 | ø12 | ø14 | ø16 | ø18 | ø20 | ø25 | ø32 |

| Minimum Clamping Length (mm) |

38 | 43 | 53 | 28 | 28 | 33 | 38 | 38 | 41 | 41 | 43 | 49 | 53 |

| Torque (N-m) |

110 | 520 | 900 | 16 | 23 | 45 | 90 | 110 | 185 | 240 | 330 | 450 | 650 |

Balancing G2.5 @ 25000 RPM