Description

Machine Design

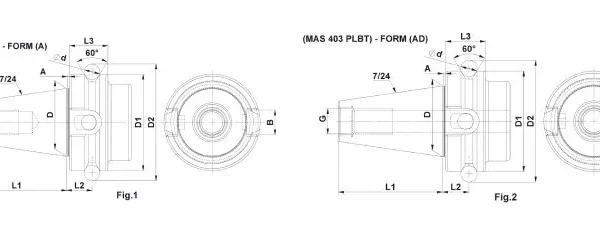

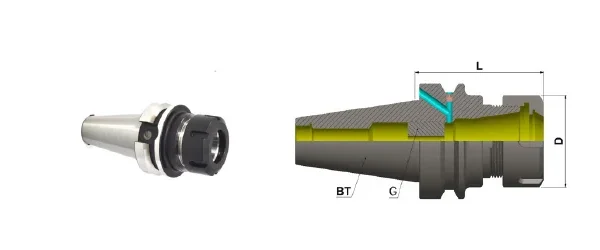

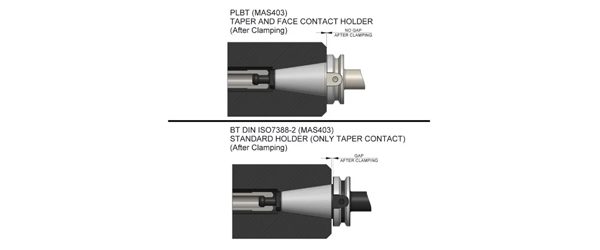

PLBT Tool holders are used to have Taper and Flange Face contact with Spindle. Here the taper of the tool holder contacts the machine spindle taper and then because of the pull force, spindle gets expands until the flange face of the tool holder touches the spindle face. Taper and face contact ensures higher rigidity resulting in improved cutting Performance. These PLBT holders should be used in the PLBT spindle machines only

PL BT (Face Contact)

- Taper and face contact

- AT-3 class taper

- Improved stability, minimizes vibration

- Greater bending stiffness for higher cutting data & productivity

- Enhanced rigidity

- Taper size 30,40,50

- Concentricity < 5µ T.I.R

- Balancing – 2.5G

- Extended tool life