Description

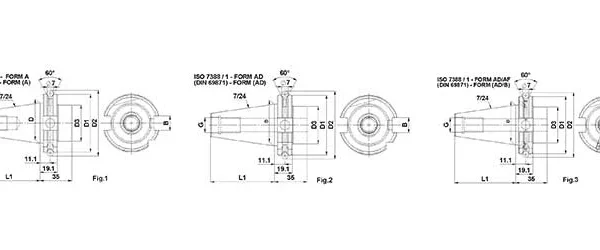

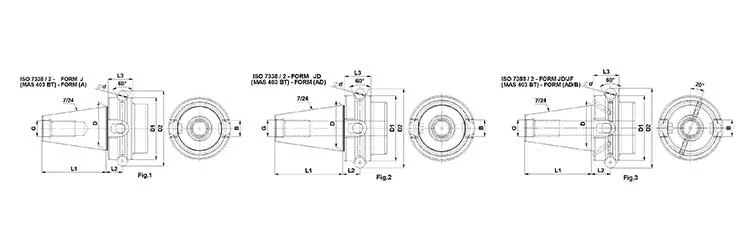

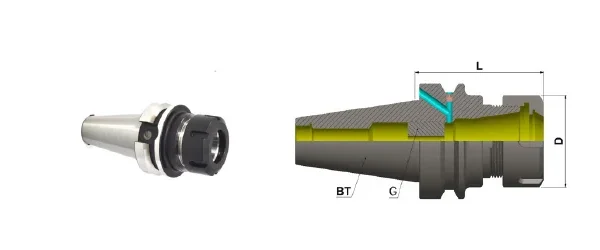

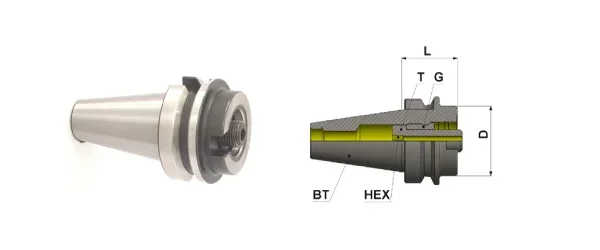

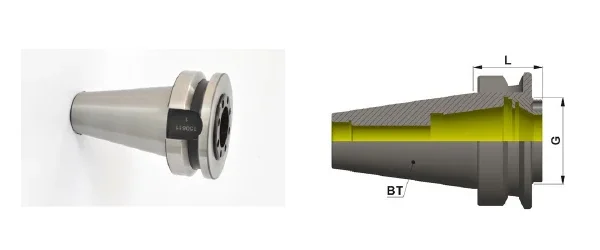

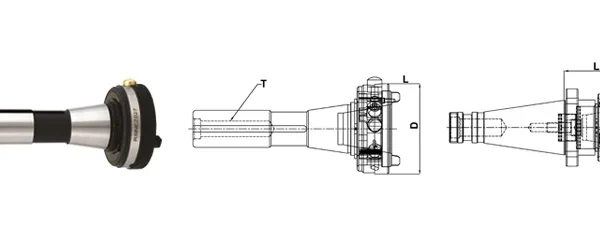

BT shanks are one of the most common tooling systems used. It is the 7/24 taper from Japan. It is available in both Centre through coolant – Form JD (AD) and flange through coolant – Form JD/JF (AD/B) It is the first instance of the 7/24 taper available with automatic tool changer (ATC) BT tool holders use metric pull studs (retention knobs). Falcon offers BT tool holders in sizes BT30, BT40, BT50 and even offers BT15 taper tool holders on request. All BT tool holders made in Falcon conform with AT3 class tolerance and are case hardened.

| Machine Design | TAPER ISO | D | D1 | D2 | L1 | L2 | L3 | d. | B | G | e1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BT30 | 30 | 31.75 | 46.0 | 56.14 | 48.4 | 13.6 | 22 | 8 | 16.1 | M12 | 20 |

| BT35 | 35 | 38.1 | 53.0 | 61.97 | 56.4 | 14.6 | 24 | 9 | 16.1 | M12 | – |

| BT40 | 40 | 44.45 | 63.0 | 75.68 | 65.4 | 16.6 | 27 | 10 | 16.1 | M16 | 27 |

| BT50 | 50 | 69.85 | 100.0 | 119.02 | 101.8 | 23.2 | 38 | 15 | 25.7 | M24 | 42 |

Pre balanced G6.3@15000 RPM

Fine balancing G2.5@25000 RPM on request